Where Art Meets Engineering

For nearly a century, Lowther has cultivated rare skills that transform raw materials into musical instruments.

In our Norfolk workshop, surrounded by the rolling English countryside, every cabinet, cone and coil is shaped by hand.

Each creation reflects the values that have guided us since 1934: purity, precision and a deep respect for natural sound.

Lowther loudspeakers are not products of automation. They are works of human artistry, refined through time and experience.

Like a violin or a fine timepiece, a Lowther is built to endure, to improve with age, and to be cherished for generations.

Philosophy of Craft

Every Lowther begins as an idea rooted in the geometry of sound.

Paul Voigt's original tractrix horn equations, conceived almost a century ago, still define our approach today.

We do not chase novelty. We pursue truth. Each instrument is designed to reveal music as it was intended to be heard, with nothing added and nothing taken away.

Our craftsmen build with an intimacy that machines cannot match. The slight variations of hand shaping, sanding and fitting bring life and individuality to each piece.

This is not manufacturing. It is interpretation, an understanding between the craftsman and the material that results in something truly unique.

Cabinetry

The creation of a Lowther cabinet begins with exact mathematical drawings, followed by hundreds of hours of precision work.

Each horn follows Voigt's acoustic principles, guiding sound waves through carefully calculated curves that preserve musical integrity.

We use only the finest Baltic Birch plywood, selected for grain, strength and tone. The bending of wood is performed using the same methods found in violin making.

It is steamed until pliable, then shaped slowly by hand, held in place until it cools and sets naturally. No shortcuts, no composites, only pure materials shaped with care.

Veneering is treated as an art form. Our clients choose from a curated collection of rare woods such as rosewood, olive, walnut and zebrano, each book matched to form a continuous grain pattern. Traditional hide glue and multiple hand rubbed layers of lacquer create depth, warmth and a surface that matures beautifully with time.

Drive Units

At the heart of every Lowther lies its voice coil, hand wound to tolerances measured in microns.

This component defines the Lowther sound, fast, pure and uncoloured.

Our craftsmen wind each coil by hand, using copper, silver or gold alloy wire depending on the collection. No machine can replicate the precise tension and layering that gives each Lowther its unmistakable signature.

Our paper cones are treated individually with a proprietary solution and dried in natural sunlight.

This process produces a cone that moves with exceptional speed and delicacy, revealing textures in instruments and voices that other materials cannot reproduce.

Every coil is then centred by hand, aligning the magnetic gap with an accuracy that depends entirely on the craftsman's eye and touch.

Each step is deliberate, each decision audible. That is why we can produce only a handful of drive units each day, and why every one carries the character of its maker.

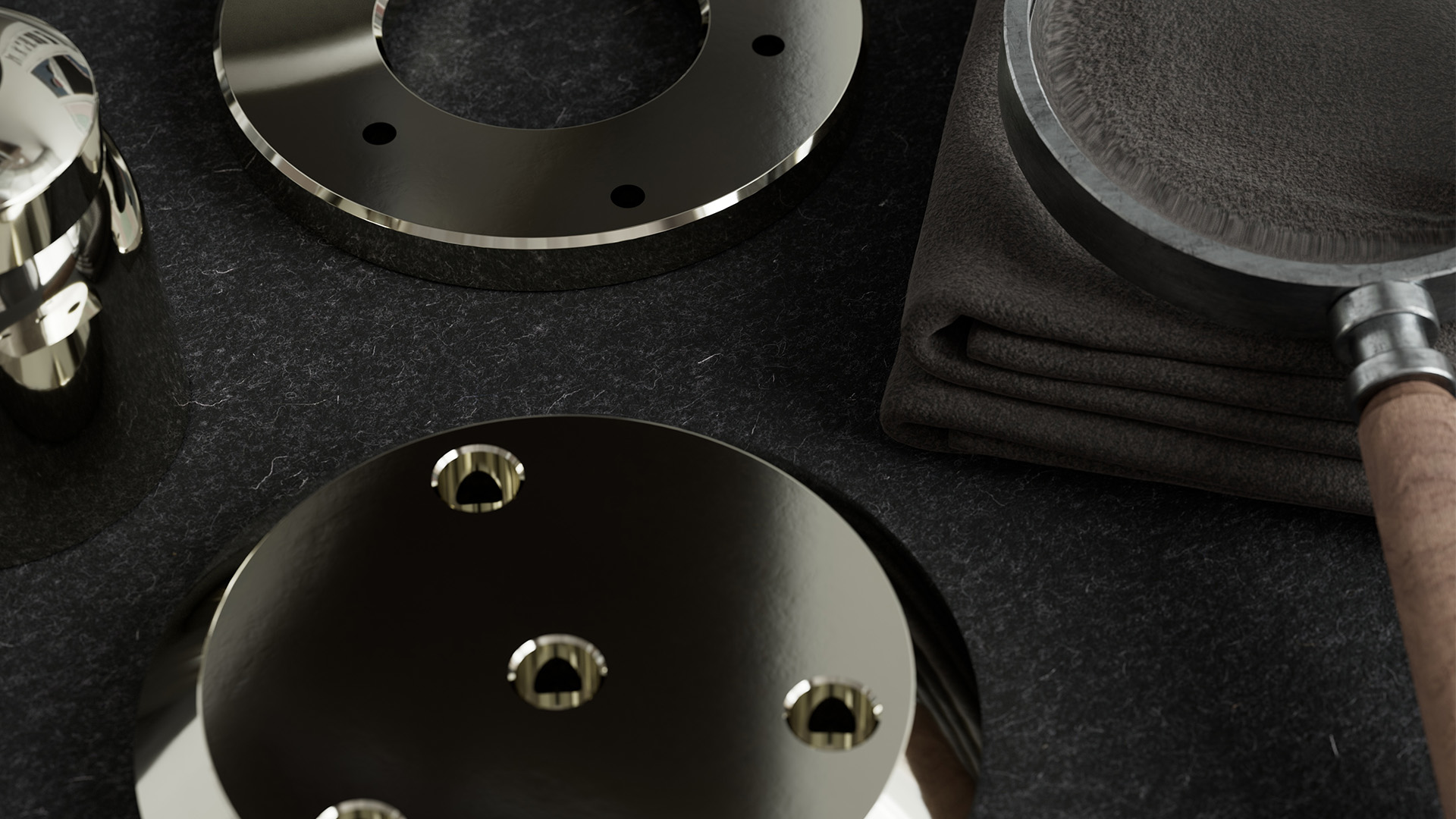

Metalwork

Lowther metalwork is engineered to a standard more akin to precision watchmaking than to loudspeaker production.

Every part that shapes the magnetic circuit is machined from solid lead free steel or Alnico, chosen for its unique magnetic qualities and harmonic warmth.

In our Philharmonic and Grand Opera collections, the metalwork reaches its most advanced form.

Components are polished and chromium finished to military standard, then assembled by hand to tolerances measured in microns.

The result is not just visual beauty but functional perfection, improving efficiency, detail and tonal refinement across the entire frequency range.

For the Grand Opera Collection, we use aerospace grade Permendur and Magmax alloys, materials usually found in particle accelerators and nuclear applications. These allow our instruments to reach levels of clarity and realism unmatched in the world of high fidelity.

Legacy of the Atelier

In an age of disposable technology, Lowther stands apart.

Our Norfolk atelier preserves crafts that have almost vanished from the modern world. Every instrument is built to order, numbered, and tested by ear as well as by measurement.

The people who create Lowther loudspeakers are not factory workers. They are artisans who understand that the smallest detail can shape the character of sound.

Their work ensures that each Lowther leaves our workshop not simply as a product, but as an heirloom, a fusion of British tradition, engineering excellence and musical soul.